Photovoltaic (PV) panels are one of the most popular and environmentally friendly sources of renewable energy. According to the International Renewable Energy Agency (IRENA), the installed capacity of PV panels worldwide reached over 700 GW in 2020, and is expected to grow to over 1500 GW by 2030. However, for PV panels to effectively contribute to green energy production, proper maintenance and servicing are essential.

PV Panel Maintenance – What Does It Involve?

PV panel maintenance involves regular checks of their technical condition, cleaning from dust, dirt, and snow, repairing any damage and faults, and optimizing their performance and lifespan.

PV System Inspection

PV system inspection focuses on elements such as technical condition verification, controls and tests, monitoring of energy production, and supporting systems for the farm’s operation.

Cleaning Solar Panels

Cleaning is a crucial part of PV panel maintenance. Any contamination can reduce the efficiency of the system.

Monitoring PV Systems

Monitoring systems allow for real-time tracking of energy production. They also enable monitoring of energy consumption and performance. With these systems, it’s possible to detect faults early, and all data can be analyzed to optimize the operation of the solar farm.

Discover Our Proprietary Monitoring System:

EMACS

What Are the Innovations in PV Panel Maintenance?

Traditional PV panel maintenance requires frequent and time-consuming human involvement to physically check, clean, and repair panels. However, technological advancements have introduced innovations in PV panel maintenance that can automate and simplify the process. Here are some of them:

PV Panel Cleaning Robots

These devices can automatically move across the surface of PV panels and remove contaminants using brushes, water, air, or other methods. PV panel cleaning robots can operate in various weather conditions without damaging the panels and with minimal energy consumption.

PV Panel Inspection Drones

These unmanned aerial vehicles can capture high-quality images and videos of PV panels from different angles and distances. Inspection drones can use specialized thermal cameras to show temperature distribution on the panels, indicating potential damage or overheating.

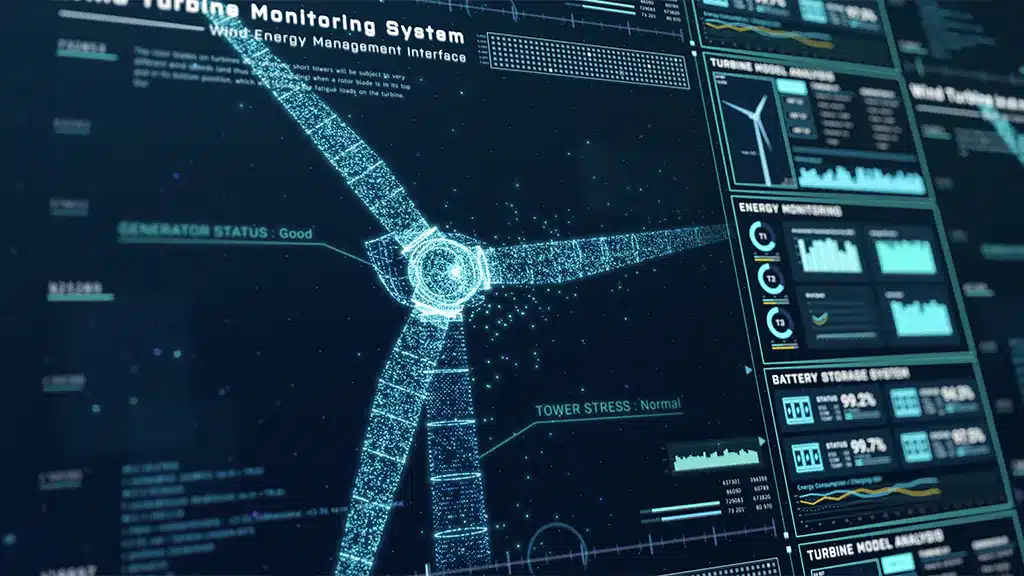

PV Panel Monitoring and Diagnostic Systems

These are software and hardware solutions that enable remote tracking and analysis of PV panel performance parameters, such as:

- Voltage

- Current

- Temperature

- Power

- Efficiency

Diagnostic systems can detect and report any anomalies, damage, or performance drops, allowing for quick intervention and repair.

What Are the Benefits of Professional PV Panel Maintenance?

PV panel maintenance is essential because it impacts several key aspects of their operation, including:

Efficiency

Maintaining PV panels prevents efficiency losses caused by contamination, shading, damage, or material degradation. Studies show that regular cleaning of PV panels can improve their performance by up to 30%.

Lifespan

Maintaining PV panels extends their lifespan, which depends on material quality, weather conditions, and operational factors. Regular maintenance helps detect and fix issues, potentially extending the lifespan of panels by up to 10 years.

Safety

Additionally, maintaining solar panels ensures safety for both users and the environment. Malfunctioning or damaged PV panels can pose fire, electrical, or mechanical hazards, and may emit harmful substances into the atmosphere or soil. Therefore, PV panel maintenance should be performed by qualified and certified specialists.

Preventing Financial Losses

Faulty or damaged PV panels can lead to reduced energy production, and even fires or electric shocks. Regular maintenance helps prevent such issues, enhancing safety and cost savings.

PV panel maintenance: Summary

Maintaining solar panels is a crucial aspect of managing PV farms. In other words, it involves managing PV panel arrays installed over large areas that supply energy to the grid or local consumers. Managing PV farms requires not only monitoring and keeping PV panels in good condition but also optimizing their performance, costs, and profits, as well as minimizing their environmental impact. PV farm management is a complex and multi-dimensional process that demands advanced tools and methods.

Also read:

The Impact of Energy Efficiency on Industry and the Environment

The Impact of Energy Efficiency on Industry and the Environment

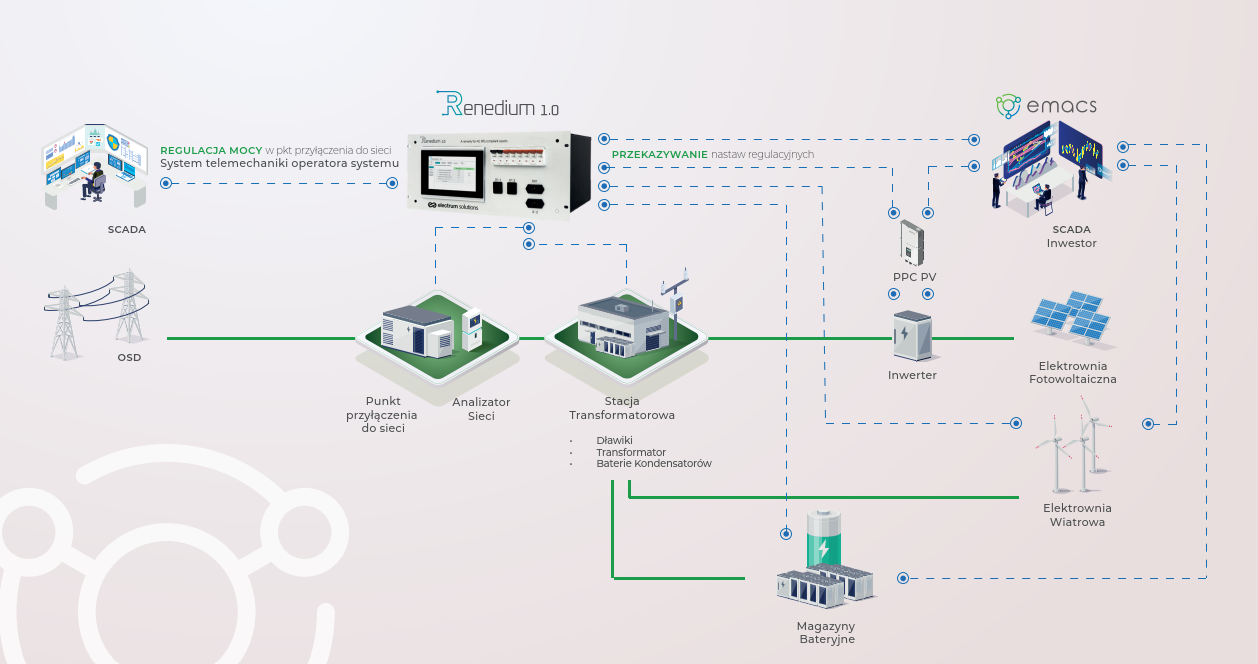

Renewable energy sources (RES) are a key element in combating climate change and meeting the growing demand for electricity. However, to realize the full potential of RES, it is not enough just to install more photovoltaic

Renewable energy sources (RES) are a key element in combating climate change and meeting the growing demand for electricity. However, to realize the full potential of RES, it is not enough just to install more photovoltaic

Photovoltaic farms are one of the most important sources of renewable energy (RES) in the world. However, to ensure their high efficiency and reliability, regular and efficient servicing is essential. In this respect, we can already rely on several innovative technologies that can make the servicing process of photovoltaic farms and wind farms easier and more efficient

Photovoltaic farms are one of the most important sources of renewable energy (RES) in the world. However, to ensure their high efficiency and reliability, regular and efficient servicing is essential. In this respect, we can already rely on several innovative technologies that can make the servicing process of photovoltaic farms and wind farms easier and more efficient These three technologies represent promising solutions for the future of PV farm servicing. However, what measurably translates into better RES facilities is their efficient management. For this purpose, systems such as

These three technologies represent promising solutions for the future of PV farm servicing. However, what measurably translates into better RES facilities is their efficient management. For this purpose, systems such as

What is a SCADA system made of?

What is a SCADA system made of?