Hydrogen has been called the fuel of the future for many decades, though in reality, this term has only gained real meaning in recent years. The development of zero-emission hydrogen technologies is driven primarily by the rapid decline in energy prices from renewable sources, technological progress, and the urgent need to drastically reduce greenhouse gas emissions.

Green Hydrogen in a Nutshell

Green hydrogen is an essential element of energy transformation and a pillar of implementing the European Green Deal. The hope placed in it is considerable, as green hydrogen is expected to play an important role in the process of industrial decarbonization.

The element produced in a zero-emission manner is perceived as the only option for decarbonizing all those areas that cannot be electrified. This particularly applies to high-emission industrial processes (e.g., steel production, chemicals) and heavy long-distance transport, which we discuss in more detail in this text.

How is green hydrogen produced? In short, green hydrogen is produced through water electrolysis using electricity from renewable energy sources (RES). This sustainable hydrogen production is characterized by the absence of CO₂ emissions associated with both its production and use. Thus, it is the cleanest renewable hydrogen.

The advanced technological level and progressive commercialization of the electrolysis process are driving hydrogen’s role in energy transformation.

Currently, the process of obtaining hydrogen through electrolysis with RES participation is at a high level of technological maturity. Electrolysis methods such as ALK (alkaline) and PEM (polymer membrane) are fully commercialized, and the costs of this process are systematically decreasing—according to the International Energy Agency, they have fallen by over 60% since 2010.

The development of commercial H₂ production technologies from RES is currently transitioning from the research and pilot phase to the implementation phase. As a result, green hydrogen can be used in an integrated energy system as a raw material, fuel, carrier, or energy storage.

Therefore, in this text, we will discuss key threads related to sustainable hydrogen production and the use of green hydrogen.

Quick Facts

- Poland is currently the third-largest hydrogen producer in the European Union, producing approximately 1 million tons of H₂ annually.

- Most of this is gray hydrogen. Gray hydrogen is produced through steam methane reforming (SMR), a highly emission-intensive process. This hydrogen is usually produced and consumed on-site in large industrial facilities.

- According to the International Energy Agency (IEA), in 2024, global hydrogen demand was close to 100 million tons. Its use is concentrated in the refinery, heavy, and chemical industries.

- Green hydrogen is produced in an environmentally friendly manner, without carbon dioxide emissions. This most often occurs through water electrolysis using energy from RES.

- Green hydrogen can replace hydrogen produced from fossil fuels in industrial processes such as ammonia production or petroleum refining.

- Green hydrogen can be used as a clean fuel in various sectors such as transport, industry, and energy, which helps in the transition to sustainable energy sources.

- Green hydrogen as energy storage can be used to store excess energy from renewable sources, which helps stabilize energy grids.

- In Poland, the development of green hydrogen faces various barriers related to, among other things, access to clean energy and the development of appropriate infrastructure.

Green Hydrogen – What Is It and Why Does It Matter?

Where Do Hydrogen Colors Come From?

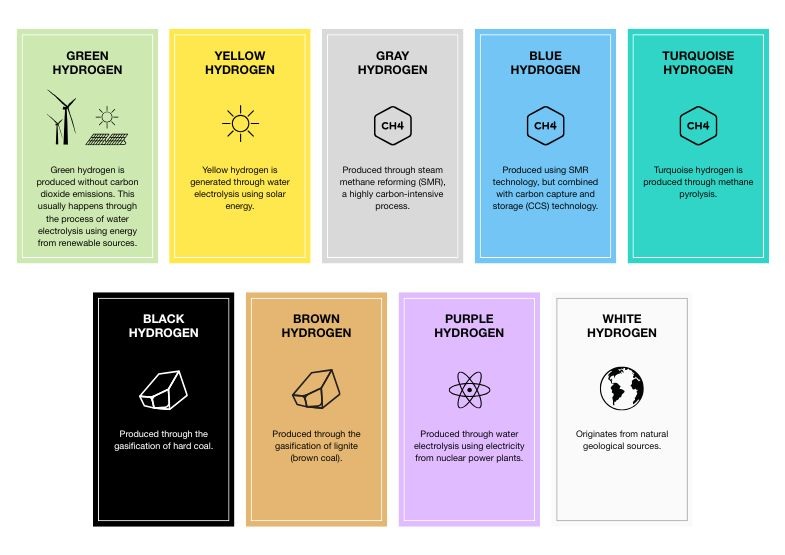

Hydrogen itself, as an element, is a colorless gas. Therefore, hydrogen colors are not the colors of the element itself, but conventional colors assigned to hydrogen extraction technology.

There are quite a few of these colors, as we distinguish gray, blue, green, yellow, turquoise, black, brown, pink (also known as purple), and white.

Fig. 1 Green Hydrogen Colors

As we mentioned in the quick facts, gray hydrogen production occurs through steam methane reforming (SMR), the main component of natural gas, at a temperature of about 1000°C.

This is the most common method of obtaining hydrogen. Unfortunately, the emissions associated with it average 9-10 kg of CO₂ released into the atmosphere for every 1 kg of hydrogen produced, as reported by the IEA.

Blue hydrogen is also obtained through SMR technology, but carbon capture and storage (CCS) technology is simultaneously used, which reduces emissions. CO₂ is stored, for example, in underground reservoirs. However, these are issues that still require research, analysis, and development of the entire market. Moreover, this does not change the fact that produced CO₂ cannot be stored indefinitely.

Therefore, transformation begins right here: in the process of replacing gray hydrogen with green hydrogen, produced mainly through the electrolysis process powered by energy from RES, making it a zero-emission method on the process side. CO₂ is not produced at all.

Green Hydrogen – How Is It Produced?

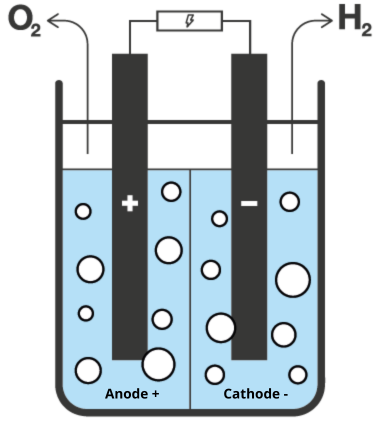

The most promising method of green hydrogen production remains electrolysis – the process of decomposing water into hydrogen (H₂) and oxygen (O₂) using electrical energy. It is carried out in devices called electrolyzers. The longest-used and still most common technology is alkaline electrolyzers (ALK).

Fig. 2 Water Electrolysis

This solution is technologically mature and increasingly widely implemented. It is distinguished by high efficiency and long component lifespan (amounting to 50–90 thousand hours). In large installations, these benefits are even more noticeable, and investment profitability is additionally strengthened by the competitive cost of the devices themselves.

💡 For us to talk about green hydrogen, it is essential that the electricity used in the electrolysis process comes from renewable energy sources.

In addition to alkaline electrolyzers, there are PEM, solid oxide (SOEC), and AEM electrolyzers – the choice of technology depends on the work profile, purity requirements, and integration with RES.

According to the World Energy Investment 2025 report by the International Energy Agency (publication: June 2025), global investments in electrolyzers increased by 90% in 2024 compared to 2023, and in 2025, they are expected to jump by as much as 150% compared to 2024, reaching a value of 2.5 billion USD.

Falling technology costs, political support, and growing private sector interest mean that the moment of commercial profitability for this technology – the tipping point – is getting closer.

What Are Alternative Methods of Green Hydrogen Production?

Water photolysis, also known as “artificial photosynthesis,” is a method using solar energy for the direct decomposition of H₂O (water) molecules into hydrogen and oxygen. This is a method remaining in the research sphere, still uncommercialized.

Thermochemical decomposition (splitting) of water – this process, requiring very high heat (from 500°C to 2000°C) and several chemical reactions, operates in a closed loop. This means that the chemical compounds used in it are constantly regenerated and reused. The only thing consumed is water, and the end products are hydrogen and oxygen.

Biological methods of hydrogen production – in these processes, microalgae and cyanobacteria play a fundamental role. Biological methods of hydrogen production can occur through photogenic means (with light participation, e.g., biophotolysis or photofermentation) or in processes independent of light (such as dark fermentation or bioelectrolysis).

Green Hydrogen Production – The Role of Renewable Energy Sources (RES)

Although green hydrogen production is technologically established, its mass scaling is burdened with challenges directly related to renewable energy. The shortage of clean electrical energy is one of the significant barriers to developing broad clean hydrogen production.

Delegated acts to the Renewable Energy Directive (RED II, and subsequently RED III) establish detailed conditions under which electrolytic hydrogen (including its derivatives, RFNBOs – Renewable Fuels of Non-Biological Origin, renewable liquid and gaseous fuels of non-biological origin) can be considered renewable.

These requirements aim to ensure that the electrical energy used for hydrogen production is additional to existing RES capacities and does not reduce decarbonization of the electricity sector.

This can be achieved by connecting the electrolyzer directly to a dedicated RES facility, such as a solar farm or wind farm.

💡 Ambitions related to green hydrogen development are closely linked to national RES development plans. For example, Poland’s green hydrogen production potential is based on offshore wind energy (a promising energy source with an estimated potential of 33 GW), as onshore wind implementation continues to be delayed due to restrictive regulations.

Green Hydrogen as Energy Storage from RES. Power-To-Gas Technology

Hydrogen has long been perceived as one of the most promising solutions for storing energy in chemical form, with the possibility of converting it back into heat or electrical energy.

An important concept in this area is Power-to-Gas (P2G) technology. It involves converting excess electrical energy, for example from wind or solar farms, into gaseous energy carriers – primarily green hydrogen (using electrolysis), and then, in a further stage, also into synthetic methane.

Hydrogen produced in this way is characterized by high energy density and is suitable for long-term storage, allowing for its rapid use when needed.

Thanks to P2G technology, it is possible to utilize surplus energy from RES or nuclear power plants, as well as integrate the electrical system with the gas system, which contributes to optimizing and stabilizing the entire energy system.

In practice, when there is surplus green electrical energy in the grid that cannot be immediately consumed, it is directed to electrolyzers. The hydrogen produced thanks to this can be further stored and used where needed – as fuel or raw material – thus creating so-called long-term energy storage (seasonal storage). Sounds good, right?

In modern energy systems of the future, RES, green hydrogen, energy storage, and developed transmission infrastructure will create a coherent ecosystem in which hydrogen as an energy carrier will play an important role.

Increasing the share of RES in national energy mixes is at the forefront of the main goals of global energy transformation. However, a significant challenge in transitioning to renewable energy sources is the instability of these sources, hence the need to seek effective ways to store energy. Power-to-Gas technology has a chance to excel in this regard.

💡 Hydrogen acts as a bridge between variable RES production and processes that cannot be easily electrified: refineries, steel, glass, cement, and chemistry. When wind and sun produce more than the system can accept, electrolysis-based systems can “absorb” surpluses, converting them into fuel and energy storage – with the potential for long storage and logistics outside the grid. This doesn’t replace batteries or cables but adds another, industrial dimension of flexibility.

Green Hydrogen and Climate Goals

Europe’s ambitious goal is to decarbonize all economic sectors and achieve climate neutrality by 2050. And as we mentioned earlier, green hydrogen has the potential to directly replace fossil fuels in sectors difficult to electrify.

However, the current scale of green hydrogen production is still small relative to overall hydrogen needs. Global and European reports – such as the Global Hydrogen Review 2024 by the International Energy Agency – indicate that hydrogen is only beginning to play a real role beyond narrow industrial applications.

EU regulations (RED III) require that by 2030, 42% of hydrogen consumed in the EU industry comes from renewable sources. The EU REPowerEU plan aims to produce 10 million tons of renewable hydrogen in the EU and import 10 million tons of renewable hydrogen by 2030. Will these goals be achieved? For now, we cannot be certain of anything, but we still have 4 years to try.

Uncertainty is also related to the implementation of the Polish Hydrogen Strategy. The Polish Hydrogen Strategy established 6 specific goals and 40 tasks covering industry, energy, and transport. The Polish Hydrogen Strategy includes, among other things, the construction of not-yet-existing hydrogen power plants and heating plants, as well as goals for hydrogen vehicles. The goal is to achieve 2000 MW of installed capacity in low-emission hydrogen production facilities by 2030 and create five hydrogen valleys.

As we cited in one of our articles, at the global and national level, we must seek business niches where green hydrogen makes sense technically and economically. Such projects are already beginning to appear – and this direction is worth developing.

Applications of Green Hydrogen in the Economy

💡 At this stage, it is important to consider where and how to use the limited amount of available green hydrogen. In the coming years, this amount will certainly not be sufficient for all potential applications. Therefore, public funds and efforts should be directed primarily at decarbonizing those areas of the economy that cannot be electrified.

Many strategic documents (as we know from, among others, the report “The Race for Hydrogen. Countries and Their Hydrogen Strategies” by the Polish Economic Institute) treat the industrial sector as a priority because it is potentially the largest recipient of clean and low-emission hydrogen due to the lack of alternative decarbonization options in high-emission processes.

Heavy Industry and Metallurgy: Emission Reduction in Steel Production

Green hydrogen can help decarbonize heavy industry, especially in processes requiring high temperatures, such as steel and cement production. The process of enriching iron ores through hydrogen reduction represents a potential alternative to traditional methods, which can contribute to reducing CO₂ emissions by 70-90% compared to conventional steel production processes.

Achieving zero-emission steel production is key to Europe’s climate neutrality assumptions because, as shown in many sources, including the report “Steel Industry in Poland” by WiseEuropa, the steel industry itself accounts for approximately 2.5% of emissions in Poland, 5% of CO₂ emissions in the EU, and about 7-8% of emissions worldwide.

Refinery, Petrochemical, and Chemical Industries

Hydrogen production is needed to process crude oil into gasoline, diesel fuel, and other chemicals. It is in the refinery industry that a significant portion of gray hydrogen is produced and consumed. Therefore, this is one of the main sectors showing interest in green hydrogen.

In the petrochemical sector, semi-finished products from refineries (and natural gas) are processed into other chemicals such as ammonia, methanol, acetic acid, formaldehyde, or chloromethane.

Hydrogen in the chemical industry is used as a raw material for the production of many compounds, including the aforementioned ammonia and methanol, or hydrogen peroxide. Ammonia production already accounts for a significant portion of hydrogen demand in the EU, and new production capacities represent an opportunity to increase the scale of low-emission hydrogen production pathways.

💡 Currently, the refinery and chemical industries are the main recipients of hydrogen produced in Poland. As reported by the Polish Economic Institute, in 2022, oil refining and ammonia production accounted for over 96% of total H₂ demand in Poland, which amounted to over 784 thousand tons annually.

On a European Union scale, in 2019, hydrogen use in refining amounted to 3.7 million tons/year, accounting for 45% of total hydrogen demand. In this sector, as in other branches of industry, gray hydrogen obtained from fossil fuels (mainly natural gas) dominates.

In June 2025, we signed an agreement for the construction of a 5 MW electrolyzer for Gdańsk Refinery – a “turnkey” project that connects the world of renewable energy with refinery processes. This is the first such installation in northern Poland.

District Heating: Heating Buildings Without CO₂ Emissions

Hydrogen (alongside biomethane) is treated in EU regulations as the target, zero-emission fuel of the future for gas cogeneration. The heating sector is increasingly feeling pressure to modernize and use alternative solutions, including the development of hydrogen technologies.

💡 In Polish district heating, we see significant consumption of conventional fuels, especially hard coal, which in 2024 accounted for approximately 60% of total heat production in the country. The aforementioned Polish Hydrogen Strategy provides for the use of hydrogen in commercial and residential heating, as well as systemic heating.

What does this look like in 2025? Poland is in the pilot and construction phase of the first green hydrogen production hubs. The goal of some projects is to supply both industry and transport, as well as – in the longer term – provide fuel for municipal district heating.

In Elbląg, for example, a pioneering, world-first bidirectional installation based on solid oxide cells operates, producing green hydrogen. The system, integrated with the BB20 biomass block at the local combined heat and power plant, can also operate in the opposite direction – as a fuel cell, converting hydrogen back into electricity. This universal solution has dual application: it serves to produce green hydrogen (e.g., for transport) and functions as energy storage.

Hydrogen boilers in district heating are being tested in several countries. The operation of a hydrogen boiler is based on the innovative combustion of hydrogen in pure oxygen, not atmospheric air or a mixture with natural gas, which is groundbreaking on a European scale. Among others, SES Hydrogen Energy conducted functional tests of a 0.5 MW hydrogen-oxygen boiler. Its creators have begun certification work. The device is to be used for hydrogen heating of apartments in a housing estate in Śrem, Wielkopolska.

Hydrogen in Transport

Transport is an area of the economy that participates in the hydrogen revolution, standing at its very forefront, and the popularity of emission-free hydrogen-based transport solutions in Europe is steadily growing. Among Polish cities that have decided to purchase hydrogen buses are Poznań, Wrocław, Wałbrzych, Konin, and Rzeszów.

This is all because hydrogen shows higher potential in long-distance, freight, and bus transport than BEV (Battery Electric Vehicle) vehicles due to shorter refueling times and longer ranges.

As indicated by SES Hydrogen, the average range of hydrogen fuel cell buses (FCEV – Fuel Cell Electric Vehicle) can exceed 350-400 km on a full tank, which translates into increased vehicle efficiency and reduced refueling frequency. For comparison, the average range of a BEV bus is approximately 250 km. However, depending on the model and manufacturer, this value can be correspondingly higher.

Regarding the use of hydrogen in rail transport, Poland is becoming an arena for pioneering tests and investments. An example is the hydrogen locomotives developed by PESA, which are already undergoing trials in industrial conditions – among others, on KGHM sidings, where Pol-Miedź Trans tested the SM42-6Dn prototype and was very satisfied with the results regarding both traction power and fuel consumption.

Aviation, like heavy long-distance transport and shipping, is one of the segments of the transport system where it is difficult to achieve emission reduction using other methods, which is why hydrogen represents an attractive option. In the aviation sector, hydrogen application involves the production of liquid fuels based on hydrogen (synthetic hydrocarbons).

Hydrogen Fuel Cells

Hydrogen fuel cells are electrochemical devices – electrochemical energy converters – that convert hydrogen into electrical energy, performing a key function in energy storage systems.

In integrated Power-to-Gas-to-Power systems, hydrogen produced in the electrolyzer is stored and then – when needed – converted back into electricity in the fuel cell, with water and oxygen being the only by-products.

This technology finds application both in power supply security systems for buildings or industrial installations, and in transport, where the cost of cells and hydrogen tanks largely determines the competitiveness of hydrogen-powered vehicles.

For efficient cell operation, high fuel purity is very important – green hydrogen from electrolysis achieves a standard of 99.97%, allowing for its safe use in drive systems, while hydrogen from reforming requires costly purification.

As reported by the Polish Economic Institute, in Poland in 2022, 22.3 million PLN from public expenditure was allocated to research related to hydrogen technologies and fuel cells.

Green Hydrogen from RES in Poland – Challenges and Perspectives

Recent years have shown that difficult market conditions significantly slow down the development of green hydrogen-related projects. High investment costs, rising renewable energy prices, and regulatory uncertainty have caused some initiatives in the EU to be limited or completely halted. Many projects were closed primarily due to a lack of economic viability.

In Poland, a factor hindering the development of this market is the relatively high cost of producing electrolytic green hydrogen compared to other European Union countries, and the resulting narrow group of entities willing to pay for using green hydrogen in their operations.

Therefore, one of the better ideas seems to be producing green hydrogen for its own use, as the Gdańsk Refinery is doing.

Hydrogen transformation, although crucial for decarbonization, requires overcoming barriers related to the high cost of green hydrogen production (which is multiple times, at least twice as high as gray hydrogen), enormous energy losses in the value chain (low conversion efficiency), lack of developed transmission infrastructure (read more in another text of ours) and storage infrastructure, as well as the need for massive increase in RES capacity to power electrolyzers.

And just as these barriers exist, the future of green hydrogen in energy systems is perceived as an extremely important pillar for achieving full climate neutrality. Despite current challenges, there is growing conviction that with the decline in technology costs and RES development, green hydrogen will become one of the key elements of a competitive and emission-free economy.

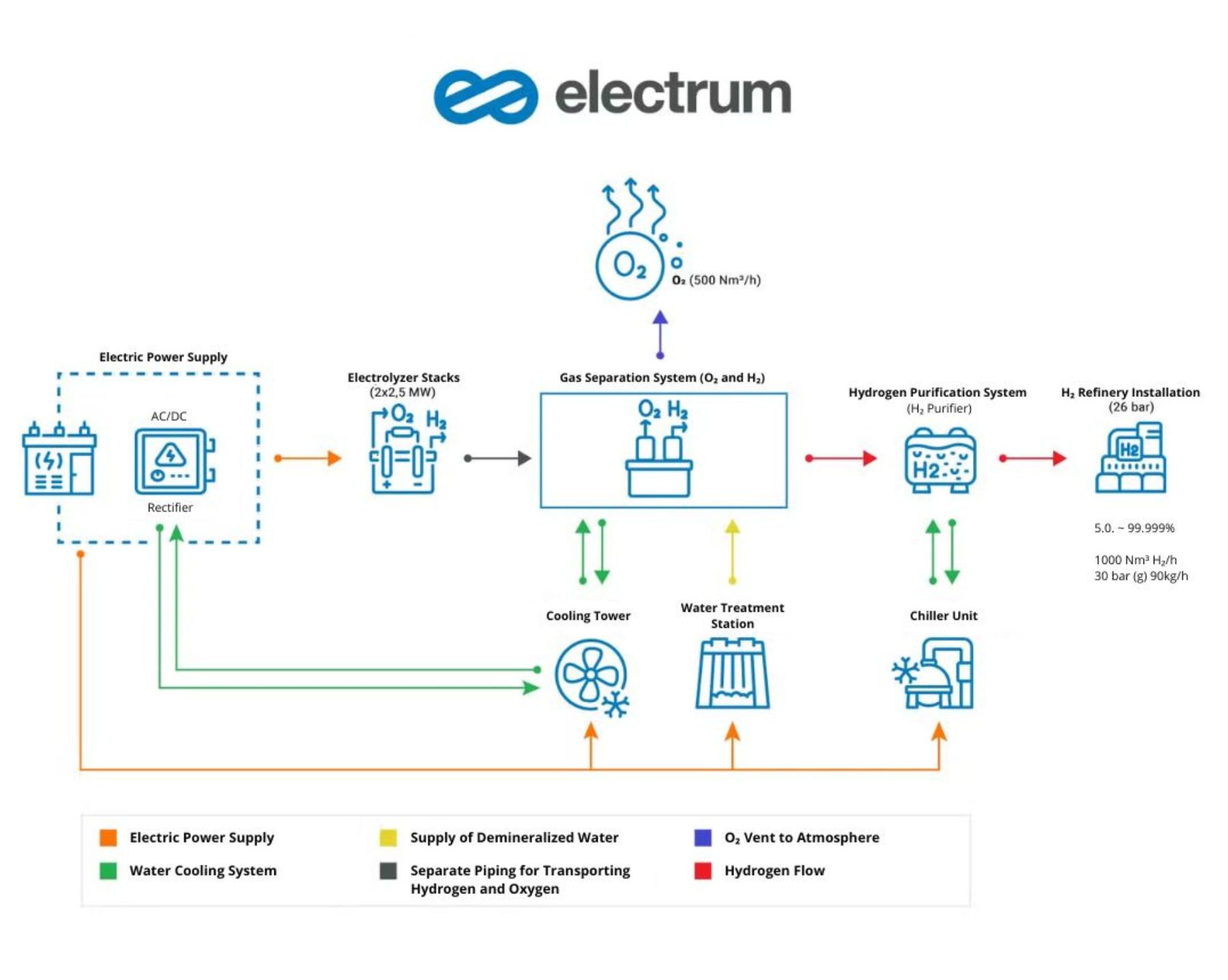

Electrum – Support in Implementing Hydrogen Projects

With nearly 30 years of experience in the energy sector and strong engineering capabilities, at Electrum, we are capable of implementing the full spectrum of hydrogen projects – from analyses and concepts, through design and installation construction, to integration with energy management systems and operational support.

We combine practical knowledge of the market and EU regulations with the ability to optimize CAPEX and OPEX, thanks to which we can translate ambitious decarbonization plans into real, effective installations.

Fig. 3 Electrolyzer at Gdańsk Refinery

Our competencies are confirmed by, among others, the “turnkey” project implemented for Gdańsk Refinery, as part of which we are building one of Poland’s largest alkaline water electrolysis installations with a capacity of 5 MW – complete with accompanying infrastructure, full technological integration, and commissioning.

This is an undertaking of strategic importance for Polish industry, showing that green hydrogen can be both an effective decarbonization tool and an element building cost and operational advantage.

Hydrogen produced in Gdańsk – 85 kg per hour with 99.995% purity, compliant with SAE J2719, PN-EN 17124, and ISO 14687:2019 standards – will supply, among others, the transport sector, opening the way for broader application of zero-emission fuels in the economy.

At Electrum, we bring to such investments not only execution competencies but also the ability to design and integrate infrastructure, which makes energy transformation visions become real projects ready for operation.

Sources

- Report “District Heating in Numbers – 2024,” Energy Regulatory Office

- Report “Global Hydrogen Review 2024,” International Energy Agency

- Report “Making the Breakthrough: Green Hydrogen Policies and Technology Costs,” International Renewable Energy Agency

- Report “The Race for Hydrogen,” Polish Economic Institute

- Report “Green Hydrogen from RES in Poland,” Polish Wind Energy Association

- Green-news.pl – Elbląg with the world’s first hydrogen source at a combined heat and power plant. The electrolyzer is powered by green energy

- Pol-Miedź Trans satisfied with hydrogen locomotive tests – Railway Market