Climate change brings an urgent need to create a new power system where renewable and zero-emission energy sources play the leading role.

One of the challenges in this process is that modern power grids were not designed for power plants where energy production is unstable. Wind and solar energy sources are highly dependent on weather conditions and time of day.

For the energy system to function uninterruptedly and stably – and thus ensure energy security – it requires constant energy balancing. It’s a time-sensitive process: at any given moment, the system must be balanced so that the amount of energy consumed equals the amount of energy generated.

Two of the mechanisms that play a crucial role in this are the balancing market and negative prices.

We invite you to read the article and interview, which provide a deeper understanding of these mechanisms. 👀

How Does the Polish Power System Work?

The National Power System is a network of interconnected components designed to ensure uninterrupted and continuous electricity supply across the entire country. To achieve this goal, it requires real-time management at all times.

This is managed through various interdependent mechanisms. In simple terms, we can explain it like this: the National Power Dispatch takes the lead, overseeing the transmission network, operated by the Transmission System Operator – Polskie Sieci Elektroenergetyczne (PSE). PSE determines the electricity demand, while Distribution System Operators – such as ENERGA, ENEA, Stoen, TAURON, and PGE – distribute electricity to end users.

For the system to operate flawlessly, precise demand forecasts and a range of market regulations are essential. These mechanisms allow for effective control of electricity intake from producers. This is where factors like the balancing market and negative energy prices come into play, directly influencing the production and consumption of energy from renewable energy facilities.

The Balancing Market

- The balancing market is a mechanism managed by Polskie Sieci Elektroenergetyczne (PSE).

- Its primary goal is to balance the supply and demand for electricity, ensuring stability and security of supply within the power system.

- The balancing market operates independently of contracts established in earlier stages of trading – its purpose is system stability, not energy trading.

- The balancing market is activated when there is a discrepancy between actual and planned energy production or consumption. In such cases, PSE instructs energy producers to increase or decrease their output.

- One of the mechanisms that can arise within the balancing market is negative prices.

Negative Prices

Negative prices occur when there is an overproduction of energy in the power system, particularly from renewable sources like solar and wind.

In such situations, system operators must implement mechanisms to balance production and demand. Negative prices arise when energy producers have to pay to feed their energy into the grid because the network cannot absorb the surplus – for example, due to low demand or system limitations.

💡 Negative energy prices are typically recorded during specific hours rather than over extended periods.

Recently, a long three-hour period of negative energy prices was recorded in the market. On September 10, 2024, between 1:00 PM and 3:00 PM, the cost of 1MWh was -50 PLN. A record? Thankfully, not in Poland. The Netherlands holds the lead here, where, on May 28, 2023, between 2:00 PM and 3:00 PM, energy was priced at -400 EUR/MWh (approximately -1847 PLN/MWh).

- Negative prices are an effective solution during the risk of grid overload, encouraging energy producers to reduce production.

- They also serve as a stimulus for developing energy storage technologies and implementing flexible solutions that allow for better control of energy production.

For renewable energy facilities, negative prices should not pose a significant challenge for a savvy investor using tools that enable precise control over production and operations. Conventional power plants, on the other hand, may struggle more with negative prices, as they cannot be easily shut down within hours.

But what happens to a renewable energy facility during an hour of negative prices?

Operation & Maintenance (O&M) in Managing Renewable Energy Facilities

- What role does Operation & Maintenance play in the effective management of renewable energy facilities, such as wind farms and solar farms?

- What happens when energy production exceeds demand?

- What tools help respond effectively to changes in energy demand?

- What tools support keeping a renewable energy facility in optimal condition?

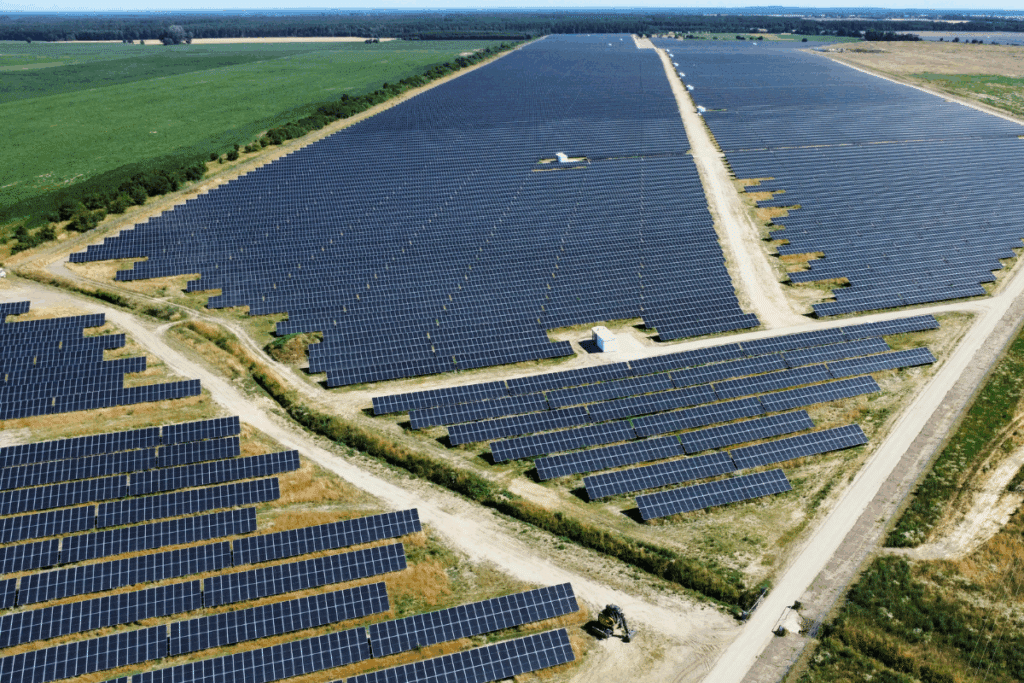

These are the questions we address in an interview with Krzysztof Kuc, Service Manager and head of the Operation & Maintenance team at Electrum Solutions. He oversees the work of skilled dispatchers, engineers, and specialists who monitor facilities generating 2.5 GW of clean energy from wind and solar every day – nearly 15% of the national production from wind and solar power plants above 1 MW.

What Do We Do When Our Renewable Energy Facility Produces Too Much Energy and We Can’t Feed It into the Grid?

Krzysztof Kuc: Unfortunately, we have to curtail generation. The systems used by PSE operators and Distribution System Operators (DSOs) can collect information on the level to which specific connection points in a given node must be limited. The operator issues a curtailment order by sending this information via email and phone.

The inability to feed energy into the grid stems from the need to balance the market. Part of this balancing involves sending forecasts of potential generation to distribution network operators well in advance. In the next step, operators reach out to us [the O&M team] with a dispatch order, instructing us to adjust the production levels of the generating unit accordingly.

So the Farm Isn’t Shut Down Completely?

KK: We try not to shut down farms entirely. If there’s no other option, we proceed with a full shutdown, but our priority is to implement so-called set points that limit the active power of the farm to a technological minimum. This way, the farm continues to operate, albeit at reduced power, allowing for a quicker return to full capacity once the restrictions are lifted.

Restarting a renewable energy facility after a complete shutdown can take several hours, resulting in significant financial and time losses. For this reason, we prefer limiting output to a technological minimum, which enables the farm to keep running with minimal losses.

And What Does the O&M Process Look Like for Shutting Down/Disconnecting a Farm, If It Becomes Necessary?

KK: A farm can be shut down remotely. However, if we shut it down with a breaker, it usually needs to be restarted locally later, because after a certain period (when the UPS batteries discharge), we lose the ability to restart it remotely. In such cases, to bring the facility back into generation, a service team must be sent on-site.

Just like a car battery that drains if the car is left unused for too long?

KK: Exactly. The most common issue is related to UPS systems, which maintain communication and the SCADA system at the farms. But they don’t always have sufficient capacity.

For example, on photovoltaic and wind farms, UPS systems have their own capacity and should maintain communication for a specific period. However, these systems often have several years of operation, and their capacity is not the same as when they were first installed. Over time, their capacity decreases, and environmental conditions, such as unfavorable temperatures or humidity, further deteriorate their condition. A UPS that initially lasted 6 hours might only last 1 hour after a few years. If we don’t restart the facility within that time, we have to send a service team on-site to restore generation.

*UPS (Uninterruptible Power Supply) is an emergency power supply device that ensures continuous energy delivery to the key systems of a farm, even in the event of an external power outage. It maintains the stability and safety of operations.

How is Energy Demand Forecasting Done? What Information Is Available to You?

KK: We receive orders to limit generation to a specific level, usually to zero. These orders are issued by the dispatchers from the Distribution System Operators (DSO) or the Transmission System Operators (TSO). Sometimes, we also receive a schedule of curtailments a day before they are implemented, particularly related to negative prices, but this information comes from the client’s representative.

In terms of energy demand forecasting, long-term forecasting is handled by the operators. They forecast energy demand on a daily, weekly, monthly, and even seasonal scale, developing strategies for determining energy consumption plans – this is called balancing. For example, in the summer, there is higher demand for energy due to air conditioning usage, and in the winter, it increases due to the need for heating.

Operation & Maintenance is Largely About Responding to Current Information?

KK: Yes, exactly. Based on information from the client’s asset management or the operator’s dispatching services, who send us requests to limit active power, adjust reactive power settings, or stop such restrictions—these are the so-called setpoints. All this is done to maintain network parameters, such as voltage, at the appropriate level.

The cooperation instructions specify how much time we have to respond to such requests. Operators also send us letters with information about upcoming curtailments, for example, around holidays. They plan everything in advance and inform us about their needs ahead of time.

Read also: Solar farm maintenance – What is the O&M Service?

Many of the ways Operation & Maintenance operates are developed on the fly, in response to changes in the market, right?

KK: When the market is constantly balancing, Operation & Maintenance has to be flexible. We work all the time. We are in continuous contact with operators, monitor their actions, and manage everything to minimize costs and risks for our clients. Operators have to react quickly when they see energy demand and generation. In situations where there is more energy available than the network can accept to maintain balance, we need to curtail the surplus but also ensure that, in case of a sudden spike in demand, we can quickly restore generation.

Read also: O&M Services Overview: Explore Our Dispatch Center | Electrum

Where Do Negative Prices Come From?

KK: Negative prices are a mechanism that allows the market to self-regulate. Transmission or distribution system operators sometimes face challenges when issuing dispatch orders. It doesn’t always work immediately, and due to the complexity of the energy system, the orders are not direct.

PSE (Polskie Sieci Elektroenergetyczne) sends production reduction orders to OSD (Distribution System Operators), who then pass them on to us, because we are the ones who oversee operations and carry out operational activities. In some cases, we receive orders directly from PSE if the farm we manage is connected to PSE’s infrastructure.

Negative prices are introduced when there is a forecasted surplus of energy. Operators find it unprofitable to take in this energy, so they should limit generation. This mechanism forces energy producers to self-limit, as no one wants to produce if they have to pay for it. As a result, those managing renewable energy assets analyze the situation and send us restriction schedules.

We do this not only considering financial benefits or losses but primarily with energy stability and security in mind.

Does this mean we’re producing too much green energy, which we’re losing? How does this work in practice?

KK: Often, we produce more energy than our system can absorb. There’s also the issue of infrastructure. During peak production, we might generate more energy than we need, but we don’t have an adequately developed transmission network to send that energy where it’s needed. For example, in May this year, many farms had to curtail energy production because we couldn’t use it effectively. Our infrastructure needs upgrading to efficiently transmit large amounts of energy from one region to another. Where there was too much energy, we had to limit it, and in places where it was needed, the system couldn’t deliver it.

So, what’s next?

KK: One of the solutions will be energy storage systems. We’re talking about battery storage, but also other types of storage, such as heat storage or hydrogen storage. With these systems, managing energy during peak hours, especially with negative prices, will be completely different, as the energy can simply be stored. Various technologies can help improve the management of energy surpluses. Of course, they won’t solve the problem 100%, but they can significantly reduce it. Biogas plants, energy storage systems, and heat storage — all of these should create an energy mix that must be managed effectively. It’s also important to forecast, predict, and properly maintain the infrastructure to respond effectively to changing energy needs. All technologies must work together within a single energy system.

At Electrum, we strive to ensure that these technologies are well integrated, and that managing this energy mix is as efficient as possible. This allows us to achieve the best results.

Read more: How energy storage systems revolutionize RES Market?

We’re talking about solutions outside of systemic investments in national infrastructure.

KK: We have a certain area of action where we can do something and maximize our capabilities, but at the same time, we do face systemic issues related to national infrastructure. We can’t avoid the fact that our transmission networks are insufficiently developed. Investments in infrastructure are necessary, but they can’t be expedited easily. These investments take a long time and cost a lot of money. Therefore, while developing infrastructure, we must also make the most of alternatives, such as energy storage and other technologies, to manage energy surpluses as efficiently as possible and ensure that the system operates as effectively as possible, including on the production management side.

Read more: Energy Project Management: The Key to Success

So, what tools in Operation & Maintenance are crucial?

KK: The key tools are various SCADA systems* and broadly understood forecasting. When it comes to forecasting, based on weather predictions — whether it’s windy or sunny — for a given location, it’s possible to determine what the expected generation should be. The appropriate data, once analyzed and processed, provide information about the generation expected from a particular source or asset for the following day. This information is then sent forward. In our dispatch center, upon receiving information about the required production, whether from the operator or the client, we use SCADA systems to apply restrictions and ensure that they are set in time and at the right level.

*SCADA (Supervisory Control and Data Acquisition) is a system that supervises and collects data in real time, enabling the monitoring and remote control of industrial processes, such as the operation of wind farms, photovoltaic farms, or power plants.

One of these systems is EMACS.

KK: Yes, it is proprietary software developed by Electrum, which offers a wide range of functionalities and improvements for asset managers and O&M operations. There is no other system on the market that provides such extensive capabilities, starting from the engineering side to managing assets and their operations. However, not all assets we manage have EMACS implemented, but this doesn’t pose any problem for us. A significant portion of the assets we handle already had a SCADA system installed earlier. In such cases, we integrate and deploy our system within our control center and train our team to use it. Not every system works the same way; some provide comprehensive information, while others may present certain issues more superficially, such as alarms or changes in the status of devices. In such cases, operators need to be more proactive in detecting irregularities or changes, which could ultimately lead to higher costs or losses for the client, for example, related to reactive power or energy dispatching.

What are the key operational and maintenance challenges for the farms you manage?

KK: The main challenge is keeping the facility in the best possible condition to ensure uninterrupted energy production. This is important both from a financial and ecological perspective. The longer the facility operates without issues, the greater its contribution to delivering green energy. Redispatching and negative prices introduce additional risks, especially when equipment is frequently turned on and off. These operations impact the lifespan of the equipment. For both wind and photovoltaic farms, turning devices on and off means additional wear, which affects their life cycle.

What about inspections? How often are they planned?

KK: Inspections should take place once a year. This is the minimum to check all equipment and ensure that everything is functioning correctly. It’s best to schedule inspections during periods of lowest generation to minimize losses. For wind farms, this is usually in the summer, while for photovoltaic farms, it’s typically after the peak sunshine season, such as late autumn.

Which tools help Electrum maintain its facilities?

KK: We have, for example, a measurement van that allows for quick and precise diagnostics of medium-voltage lines, which are the most prone to failure. With this tool, we can accurately assess the condition of the lines and plan preventive actions. It’s about detecting potential issues before they become major problems – early diagnosis enables us to plan repairs at a convenient time, which is much less costly than responding to failures. This helps avoid long downtimes and expensive repairs.

We also have a wide range of tools, including handheld thermal cameras, which allow for quick diagnostics of issues on an operating facility. Additionally, we have equipment for electroluminescence measurements, which helps assess the condition of photovoltaic panels. This is a very precise tool that shows whether there are internal cracks in the panels, which can lead to damage and, ultimately, reduced efficiency.

How do these actions translate into environmental and financial benefits?

KK: The better we manage a facility, the lower the maintenance costs and the higher its efficiency. By optimizing the operations of the farms, we also reduce the risk of energy generation interruptions, which allows for a fuller utilization of the potential of renewable sources. Ultimately, this approach supports the stability of the power system and brings us closer to a more sustainable future—based on technology, efficiency, and environmental care.